Technical Assistance Portfolio

Production facility failures and downtime result in wasted time, compromised productivity and safety, cost increasing and ultimately reduced revenue.

With our 25 years+ of experience, we Arsopi Thermal are leading experts in the inner workings of heat plate exchangers.

You depend on us to optimise PHE performance.

Service for life.

We go hand-in-hand with our partners.

ADVANTAGES OF AFTER-SALES SERVICE

- Prevent unexpected shutdown

- Streamline initial investment recovery

- Maximize production / operation efficiency and lifetime

- Simplify product quality and safety management

- Enhance PHE performance

- Optimise processes to identify and improve problems

- Repair service (on-site or at our factory)

- Fast proposal and planning of interventions and services

- Maintenance and replacement of multi-branded PHE

Preventive Maintenance

Equipment must be inspected on a routine basis to avoid any unforeseen events that could have a significant impact on product productivity.

Arsopi Thermal's highly skilled specialists conduct a condition audit of your equipment and evaluate the necessity of cleaning, repair, or upgrade etc. to propose and implement the optimal measures and solutions according to the condition.

Benefits

- Reduce the risk of equipment damage

- Maintenance plan and cost management optimisation

- Ensure safe equipment operation and secure production stability

- Reduce equipment cost and deterioration

- Extend equipment life

Repair

Our specialists repair the equipment upon your requests and can offer a set of standard service packages according to your needs.

Benefits

-Minimize downtime

-Maximize production capacity

-Extend equipment life

-Prevent indirect damage and accidents

-Reduction of energy and operating costs

-Maintenance cost reduction

Updates & Modifications

As the efficiency decreases over the course of long-term operation, it becomes necessary to modify the device status and performance. Inaddition, operating conditions change over time, necessitating redesign of equipment to meet changing process, condition, and function requirements.

Arsopi Thermal offers a wide range of services to take your operations to the next level with a range of upgrade and modification solutions that incorporate the latest technology to improve productivity.

Benefits

- Minimize wear and damage

- Extend equipment life

- Improve productivity and stability through performance optimization

- Optimize operating costs

Diagnostics & Maintenance

Regardless of industry or application, there will always be a need for high-performing and reliable heat exchangers.

Based on our rich experience, Arsopi Thermal will advise you on regular maintenance periods and methods to maintain the performance level of your equipment and provide optimal maintenance services that keep operating costs low.

A periodic maintenance contract for your equipment is also available through various service packages.

Benefits

- Maintain safe equipment operation

- Ensure operational reliability and security

- Extend equipment life

- Reduce operating costs

Services can be conducted site or at our service factory.

Arsopi Thermal can offer a set of standard service packages can be adapted to your needs.

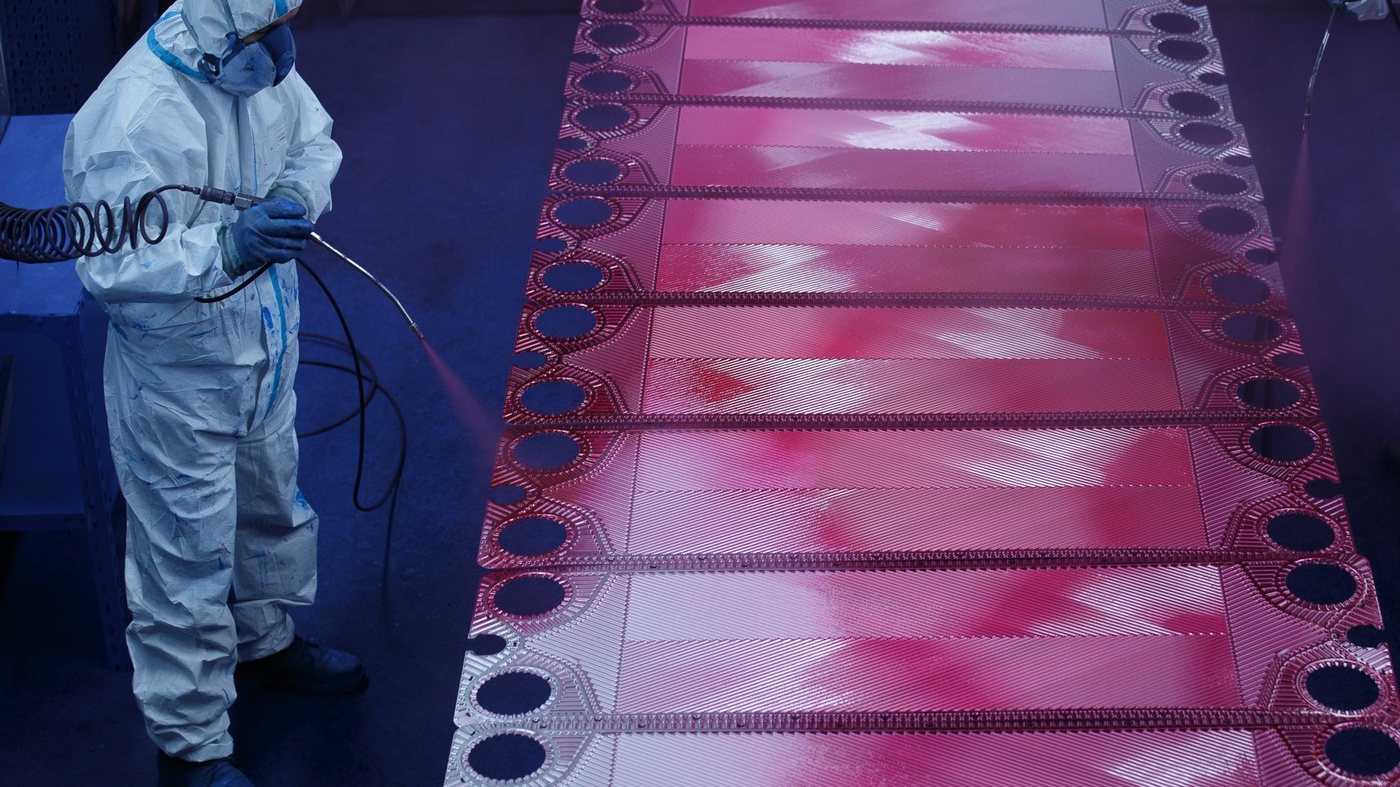

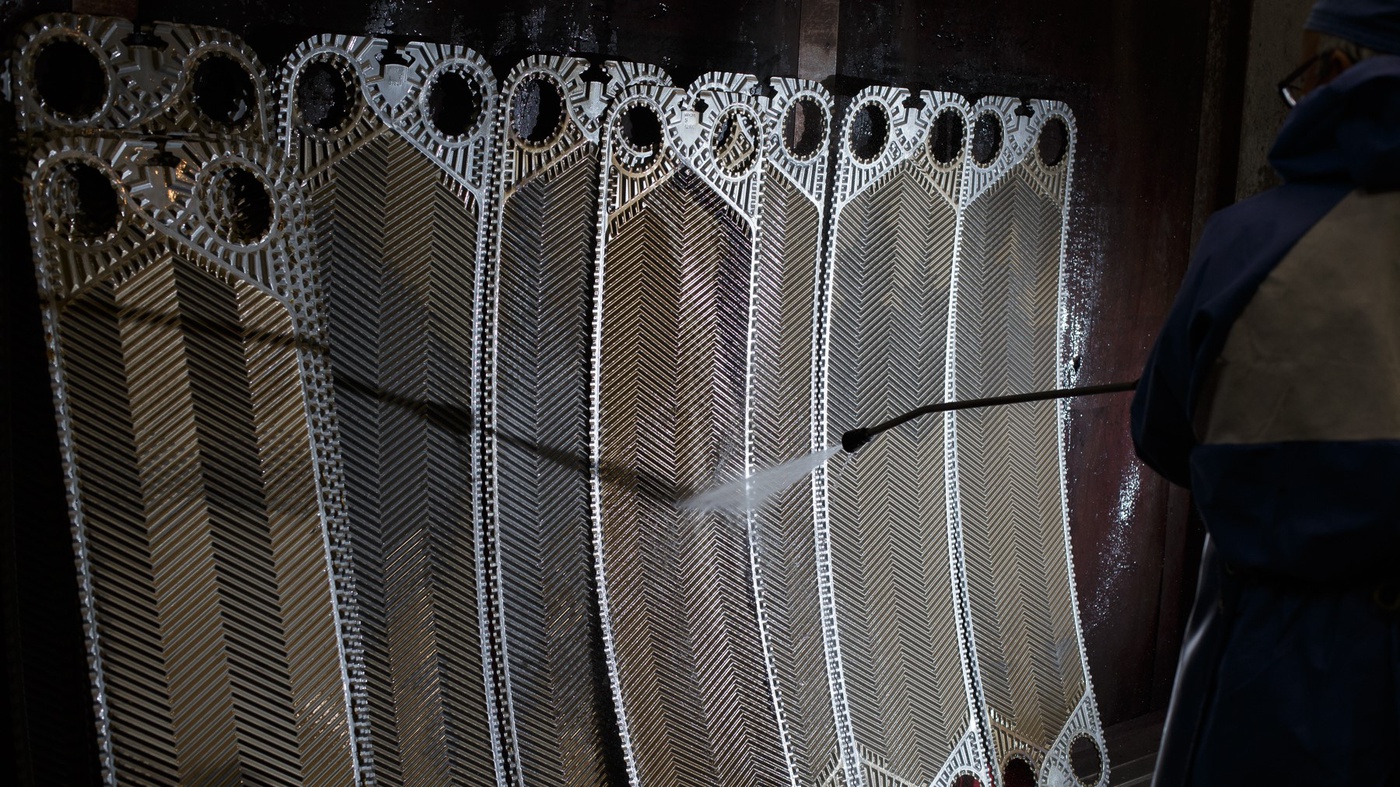

AQUA: Basic washing service for all heat exchanger plates

Xpress-A: AQUA service with Hydraulic Test

SUPER: Chemical washing service for all heat exchanger plates

Xpress-S: SUPER service with Hydraulic Test

PREMIUM: Chemical washing service and penetrating liquid testing of all heat exchanger plates

Diagnostic: Diagnostic and visual inspection service for plate heat exchangers

Hydraulic Test: Hydraulic testing on plate heat exchanger

Frame Renewal: Frame overhauling to improve the plate heat exchanger frame

| Services | AQUA | Xpress A | SUPER | Xpress S | PREMIUM | Diagnostic | Hydraulic Test | Frame Renewal |

|---|---|---|---|---|---|---|---|---|

| Opening heat exchanger | √ | √ | √ | √ | √ | √ | ||

| Gasket removal | √ | √ | √ | √ | √ | |||

| Plate water washing | √ | √ | ||||||

| Plate chemical cleaning | √ | √ | √ | |||||

| Penetrant test (full plates) | √ | |||||||

| Gaskets visual inspection | √ | √ | √ | √ | ||||

| Gasket thickness measurement or validation | √ | |||||||

| Gasket application / bonding | √ | √ | √ | √ | √ | |||

| Plate placement execution | √ | √ | √ | √ | √ | |||

| Visual inspection of exchanger structure | √ | √ | √ | √ | ||||

| Visual inspection of exchanger IN / OUT | √ | √ | √ | √ | ||||

| Plate arrangement mounting on exchanger | √ | √ | √ | √ | √ | |||

| Heat exchanger closure | √ | √ | √ | √ | √ | |||

| Technical assistance report | √ | √ | √ | √ | √ | |||

| Detailed assistance report | √ | |||||||

| Diagnostic Report | √ | |||||||

| Hydraulic test | √ | √ | √ | √ | ||||

| Frame Renewal | √ |

Consulting

Our diligent technical maintenance team offers a variety of training programs that effectively blend hands-on training to enhance your specialised team skills and broad knowledge of PHE.

A tailored training menu is also available to meet the specific needs of particular products, industries or applications.

Safety training

Operator training

Technical and maintenance training

Benefits

- Improve production efficiency

- Extend equipment life

- Contribution to equipment safety and worker safety measures

- Improve operational reliability and security

- Reduce maintenance time cost