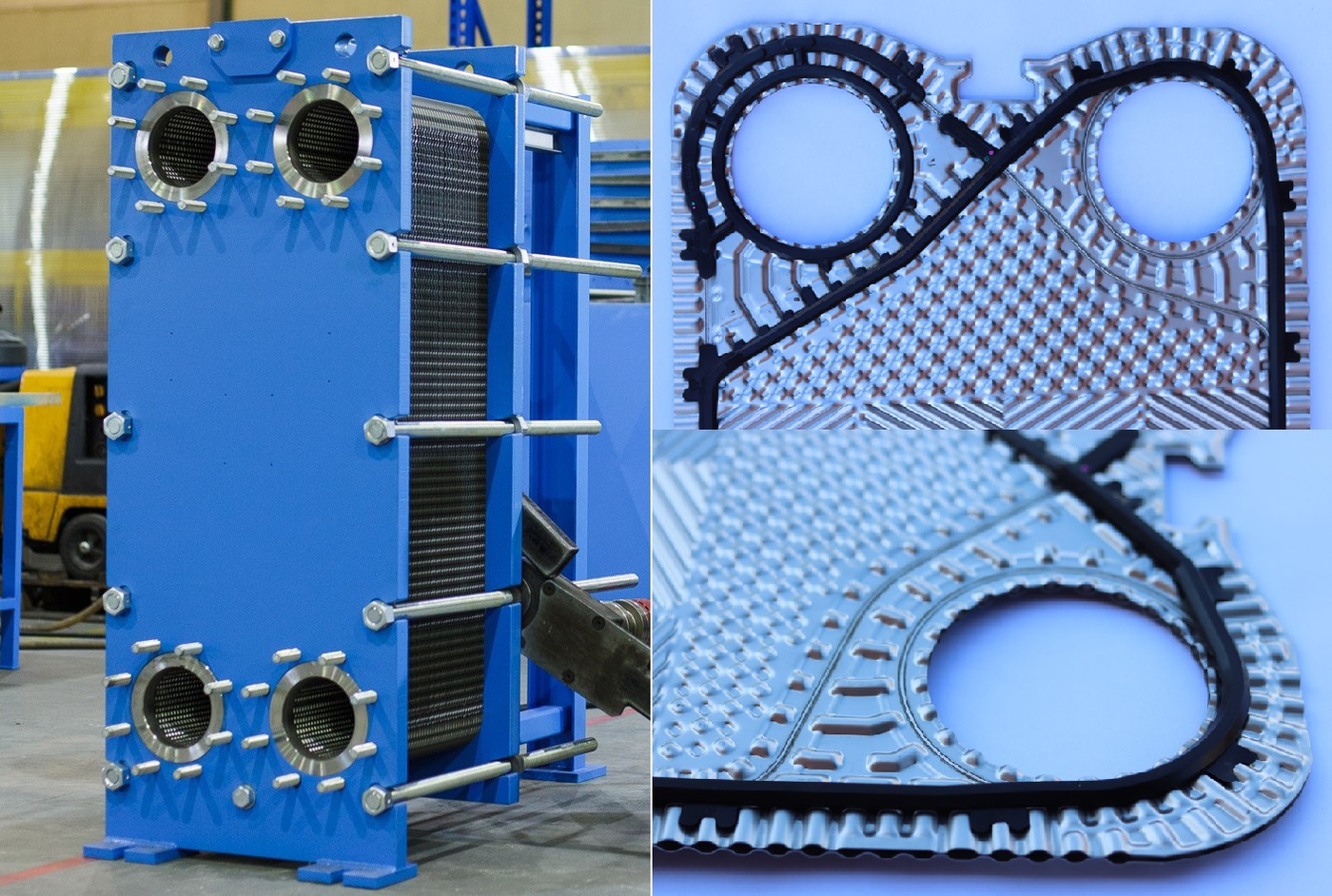

Semi-welded Heat Exchangers

High-efficiency heat transfer that requires high heat resistance and pressure resistance.

Semi-Welded Plate Heat Exchangers combine the efficiency and flexibility of a gasketed plate heat exchanger

with the strength and resistance of a welded Plate Heat Exchanger, by the use of Semi-Welded plate pack.

Main Features

A cassette is formed by two plates laser welded together with O-ring at portholes and a regular gasket on the outside.

One fluid (aggressive media or refrigerant) is flowing through the inside of the cassettes welded and the other fluid is flowing on the outside of the cassettes (standard gasketed side).

This configuration allows the use of plate technology for aggressive media and other applications where high pressure resistance or limited contact between gasket and fluids is necessary.

- Applicable to dangerous fluids and aggressive media that corrode synthetic rubber

- Suitable for heat exchange that requires high airtightness, high heat resistance and pressure resistance

- Applicable to high-purity fluids that prevent the outflow of gasket components

- Welded cassettes with possibility to use excellent chemical resistance gaskets such as PTFE gasket (TCG)

- Compact, flexible and inspectable/cleanable mechanically (gasketed side)

- Maintenance costs can be reduced for fluids with frequent gasket replacement

Specification

Capable to handle high pressure and high temperature fluids (up to 180ºC and 4 MpaG)

Conventional | Welded | |

Pressure Resistance | Up to 3.0 MPaG | Up to 4.0 MPaG |

Heat Resistance | 150˚C | 180˚C |

Applications

- Heating / cooling of fluids that corrode synthetic rubber

- Heating / cooling of dangerous fluids such as sulfuric acid

- Heating / cooling for the duty exceeding the heat or pressure resistance of gasket-type plate heat exchangers

- Heating / cooling in refrigeration cycles using refrigerant